Life Cycle Assessment (LCA): Advanced Carbon Footprint Calculations

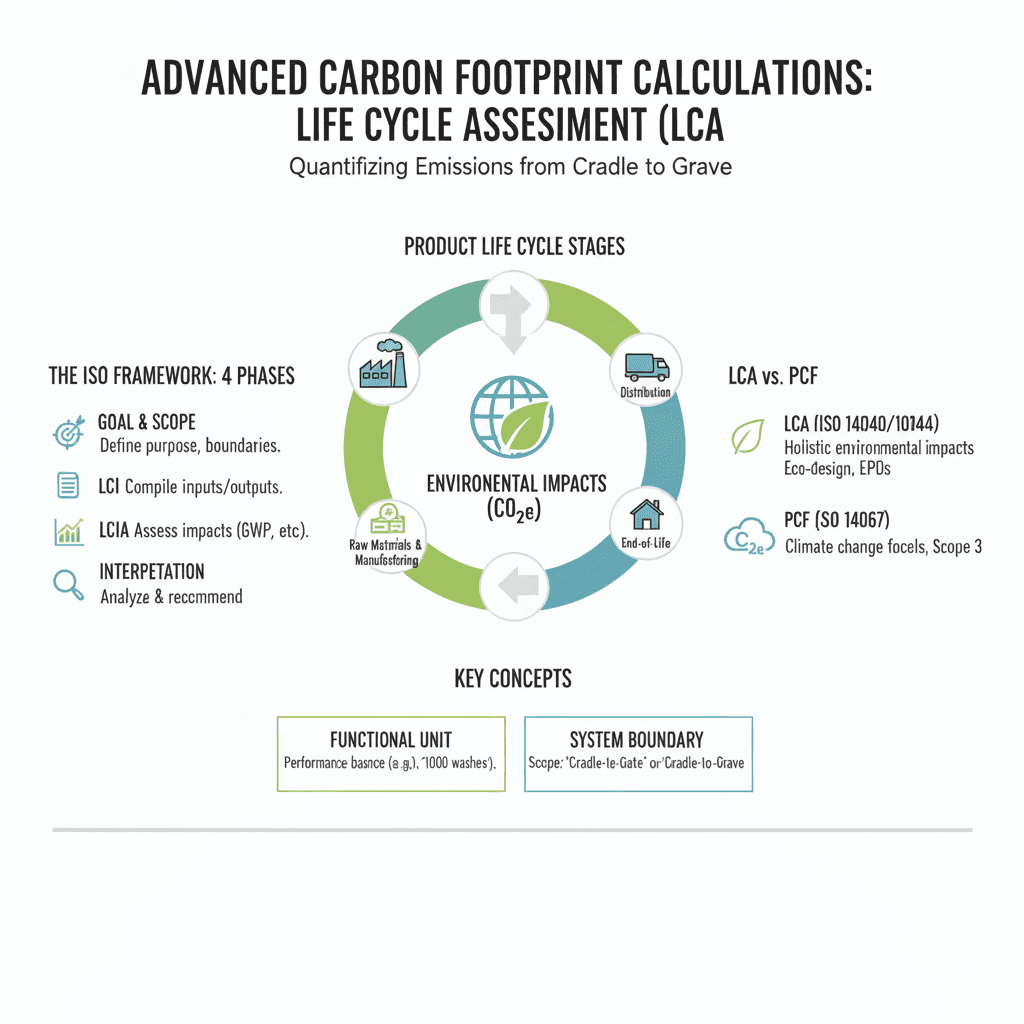

Advanced carbon footprint calculations go beyond activity-based estimates to quantify emissions across a product’s entire life—from raw materials to end‑of‑life—using Life Cycle Assessment (LCA). LCA follows a standardized, four‑phase methodology under ISO 14040/14044, and product carbon footprinting (PCF) under ISO 14067 focuses specifically on greenhouse gases. This guide explains LCA’s building blocks, how to set boundaries and functional units, data and allocation pitfalls, impact assessment choices, and how to turn results into credible eco‑design and procurement decisions.

Table of Contents

What LCA measures

LCA quantifies environmental impacts across all life‑cycle stages—extraction, manufacturing, distribution, use, and end‑of‑life—using a consistent functional unit and declared system boundaries. For carbon footprint results, the PCF under ISO 14067 expresses greenhouse gases as CO₂e across the same cradle‑to‑grave or cradle‑to‑gate model, ensuring comparability and transparency for product claims and decisions.

The ISO framework in four phases

- Goal and scope definition: Define purpose, audience, functional unit, system boundaries, assumptions, data quality requirements, impact categories, and allocation rules; align scope to intended comparisons and decisions.

- Life Cycle Inventory (LCI): Compile inputs/outputs (materials, energy, emissions) for each process, set cut‑off rules, choose datasets, and document allocation for multi‑output processes.

- Life Cycle Impact Assessment (LCIA): Map inventory flows into impact categories (e.g., global warming potential, acidification, eutrophication, resource use) and calculate category indicators with characterization models.

- Interpretation: Test sensitivity, uncertainty, and data quality; check completeness and consistency; provide conclusions with actionable recommendations and limitations.

Product carbon footprint (PCF) under ISO 14067

ISO 14067 specifies principles and requirements to quantify and report a product’s carbon footprint using an LCA approach focused on climate change impact (GWP). It maintains ISO 14040/14044 structure while narrowing to CO₂e, enabling consistent quantification, partial PCFs for specific stages, and third‑party verification/readiness for external communication and eco‑labels.

Functional unit and system boundary essentials

- Functional unit: A quantified reference (e.g., “1,000 wash cycles at 40°C”) that ensures apples‑to‑apples comparisons in design or supplier selection.

- System boundaries: Cradle‑to‑gate (A1–A3) for supplier screening and EPD stages, or cradle‑to‑grave (A1–C4) when use/end‑of‑life dominate; include packaging, transport modes, electricity mixes, and maintenance where relevant.

- Temporal and geographic representativeness: Use current, region‑specific data and disclose years, datasets, and electricity grid mixes to avoid bias.

Allocation, cut‑offs, and data quality

- Allocation: For multi‑output processes, prioritize system expansion/substitution; if not feasible, use physical (mass/energy) or economic allocation and document rationale.

- Cut‑offs: Set material/energy thresholds by mass, energy, or environmental relevance; disclose and test sensitivity.

- Data quality: Target primary data for hotspots; use reputable background databases; state pedigree (technological, temporal, geographic representativeness) and uncertainty.

Impact assessment choices for carbon and beyond

- Climate impact: Choose the GWP time horizon (commonly 100‑year) and include biogenic carbon and land‑use change as appropriate.

- Beyond carbon: LCIA can include resource use, water use, acidification, eutrophication, and more; selecting relevant categories prevents burden shifting.

- Characterization models: Follow recognized LCIA methods aligned to ISO; document versioning to maintain comparability and reproducibility.

LCA vs. PCF: when to use which

- PCF (ISO 14067): Use when the decision or disclosure focuses on climate—supplier screening, product carbon labels, carbon cost scenarios, or Scope 3 category roll‑ups.

- Full LCA (ISO 14040/14044): Use for eco‑design trade‑offs (e.g., lightweighting vs. durability), where non‑carbon impacts matter, and for comprehensive EPD work; PCF is a subset of LCA focused on GHGs.

Turning results into design and procurement action

- Hotspot‑led redesign: Focus engineering on the 2–3 processes dominating CO₂e (e.g., resin choice, energy‑intensive steps, logistics mode).

- Supplier engagement: Specify low‑carbon materials/energy, request primary data, and set improvement targets tied to the functional unit.

- Use‑phase optimization: If use dominates (e.g., appliances), redesign for efficiency and durability; if end‑of‑life dominates, improve recyclability and material recovery.

- Portfolio governance: Version LCAs, update when designs or suppliers change, and align release cycles with eco‑labels/EPDs and Scope 3 updates.

Common pitfalls and how to avoid them

- Inconsistent functional units: Define performance‑based units to avoid misleading comparisons.

- Hidden burden shifting: Use at least a core set of non‑carbon categories to catch trade‑offs.

- Overreliance on generic data: Prioritize primary data for hotspots; run sensitivity analyses on key assumptions (e.g., electricity mix, transport mode).

- Undisclosed assumptions: Publish boundary diagrams, datasets, allocation choices, and uncertainty so decisions and claims remain defensible.

Verification, EPDs, and communication

- Critical review: For comparative assertions and public claims, use ISO‑compliant critical review panels or program operators.

- EPDs: Follow program rules (e.g., EN 15804 for construction) and Product Category Rules (PCRs) to ensure consistency and comparability; map LCA results to EPD modules.

- Claims: Communicate boundary + functional unit + timeframe + data sources; avoid “carbon neutral product” claims unless residuals are small, reductions are documented, and offsets/removals are transparently retired.

Opinion: Make LCA the product team’s superpower

The value of LCA isn’t the report—it’s the iterative loop. Version 1 finds hotspots; version 2 swaps a resin, route, or supplier; version 3 redesigns for durability and repair. Teams that tie LCA to engineering sprints and supplier scorecards cut embodied and use‑phase CO₂e faster than teams that treat LCA as a compliance document.

Learn More

Explore practical next steps and foundational concepts in one place: start by testing scenarios with the free Coffset Carbon Footprint Calculator, then build fluency with our explainers What Is a Carbon Footprint?, What Is Carbon Offsetting?, and Reduce vs Offset: Why Both Matter. For more resources, visit the Coffset homepage, explore the Carbon Learning Center, or take action via Buy Carbon Credits.

FAQs – Life Cycle Assessment

- What’s the difference between LCA and product carbon footprint (PCF)?

PCF (ISO 14067) is an LCA focused on climate impact (CO₂e), while full LCA (ISO 14040/14044) can include multiple environmental categories to avoid burden shifting. - How should a functional unit be defined?

Use a performance‑based, quantified reference so alternatives are comparable (e.g., “1 m² of flooring for 20 years”), and align system boundaries to that function. - When is third‑party review required?

Comparative assertions disclosed to the public require ISO‑compliant critical review; EPDs require conformance to PCRs and program rules for credibility and comparability.

Sources

- ISO 14040/14044 overview and phases: https://help.covetool.com/en/articles/8814594-understanding-lca-standards-iso-14040-14044 and https://root-sustainability.com/blogs/iso-14040-and-14044-standards/ and video explainer: https://www.youtube.com/watch?v=42gsNQRptlo

- ISO 14067 (PCF) explainers and verification: https://oaklarpwell.com/en/news/iso-14067-as-calculating-the-carbon-footprint-of-a-product/ and https://www.sgs.com/en-es/services/iso-14067-verification-greenhouse-gases-carbon-footprint-of-products and ISO page: https://www.iso.org/standard/90578.html

- LCA guides and best practices: https://ecochain.com/blog/life-cycle-assessment-lca-guide/ and https://blue-marble.co.uk/sustainability-guides/life-cycle-assessment-lca/ and https://helpcenter.ecochain.com/en/articles/9515835-explained-lca-standards

- Carbon management and PCF context: https://ecochain.com/blog/carbon-management/ and https://rebuilt.eco/resources/rebuilt-pcfs and https://www.carbonbright.co/insight/lca-standards